easysnap 3d

Just a snap for your insoles.

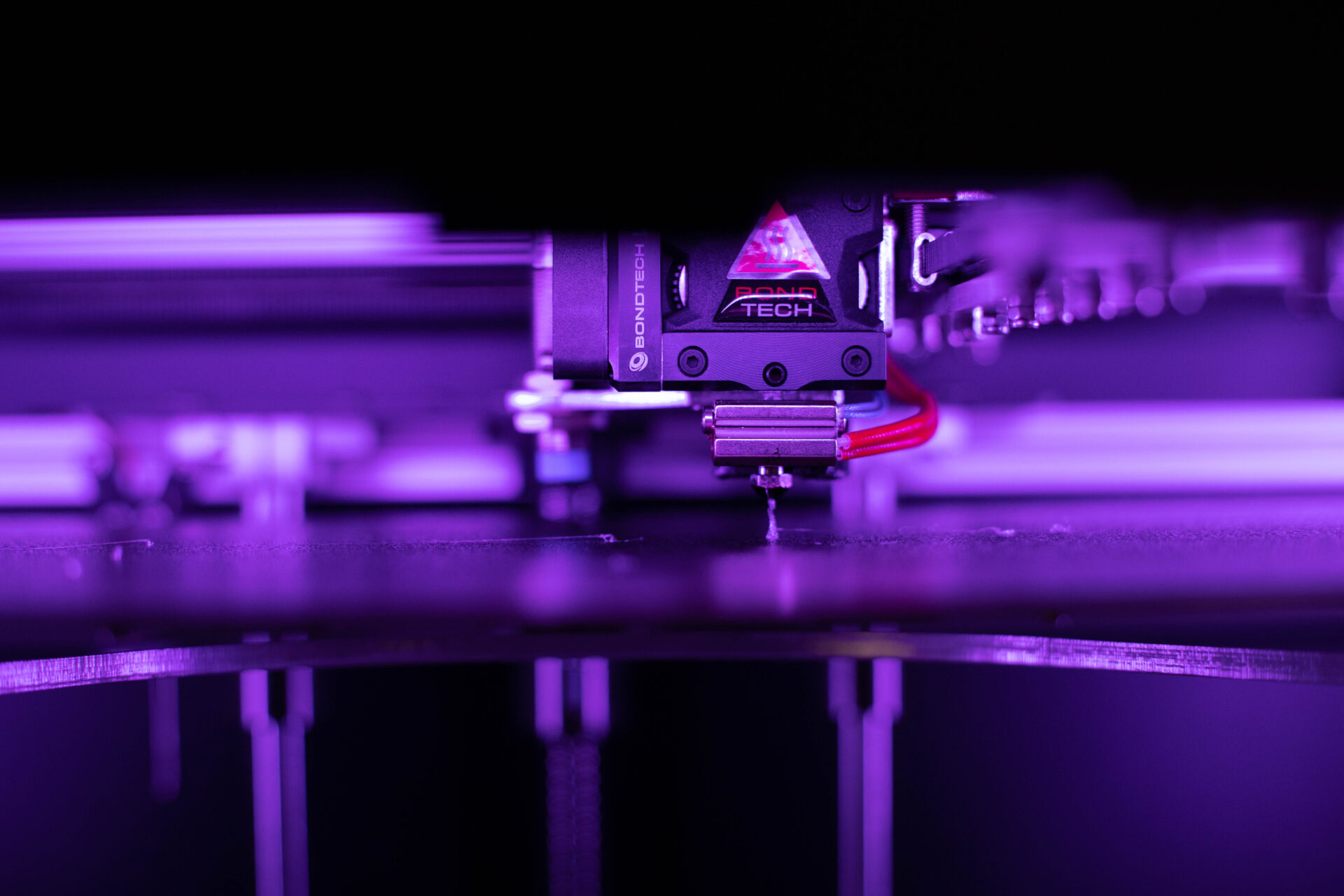

EasySnap3d is a FFF (Fused Filament Manufacturing) 3d printer developed by Sensor Medica. Its function is to transform the 3D digital models of the insoles processed in CAD, with the aid of Sensor Medica’s CAM software, into insoles by depositing fused thermoplastic filaments layer by layer. The printer is designed to work with soft filaments such as SensorTECH 85A, supplied by Sensor Medica.

Why use EASYSNAP 3D?

Connectivity: The 3D printer uses a high speed wireless connection with Wi-Fi protocol for online printing and Legacy USB connection for offline printing, granting a potential 100% uptime for your massive insole production. – Slice3D: EasySnap3D uses Slice3D, a software that uses an algorithm for printing transition zones, in order to guarantee maximum foot comfort in areas of different densities. – Fast: The device prints a pair of insoles in approximately 1 hour, depending on the shape, design and density of the orthotic.

EasySnap3D Information

EasySnap3D:

- Dimensions: 660x570x700 mm

- Weight: 37 kg

- Working area: 390x145x145 mm

EasySnap3D XL:

- Dimensions: 660x660x700 mm

- Weight: 43 kg

- Working area: 390x235x145 mm

- Nozzle diameter: 0.8 mm

- Filament diameter: 1.75 mm

- Power supply: 100-240V

- Absorption: 1.5-3.5 A

- High resolution printing from 0.1 to 0.6 mm

- Temperature up to 285°C

- Multilayer printing strategy with Shore with areas of different density, elements from 30A to 70D

- Shore hardness of the filament: from 60A to 95A

- Filament dryer included

- Printing material certified for skin contact.